Advance HydraulicRod Pump Technology

Hydraulic rod pumps provide an alternative to traditional beam units, ESP’s, PCP’s, Gas Lift, etc. combining the reliability and durability of a long stroke rod pump with a minimal wellhead footprint. Hydraulic rod pumps are ideal for well production testing, liquid loaded wells & troublesome wells, and deep or deviated wells, in addition to wells where a traditional rod pumps are considered.

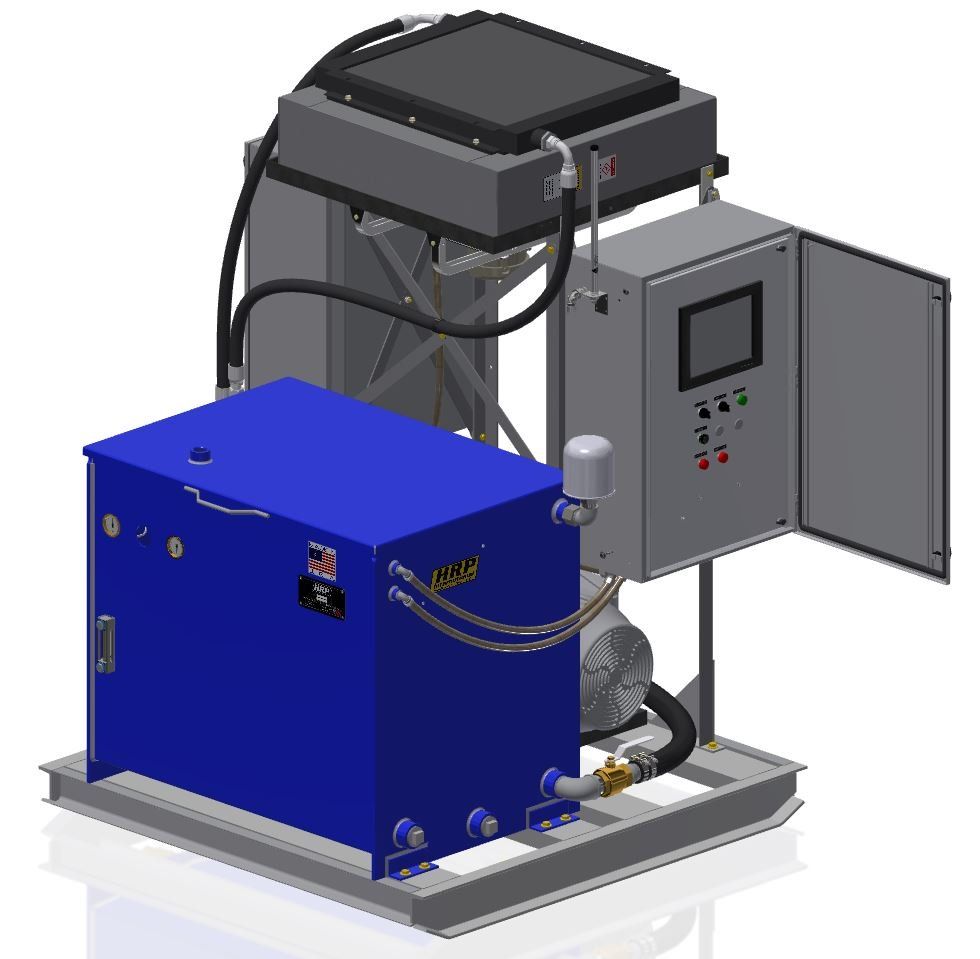

The plug & play package comes with the hydraulic cylinder and a hydraulic power unit, well operation is monitored & controlled remotely. Advance controls include pump-off controller, dyno-cards, remote web-based monitoring & control, fluid level monitoring.

Applications

HRP Hydraulic Rod Pumps are ideal in many applications including Deep Wells, Deviated Wells, Stripper Wells, Pad Wells, Dual Completions, Residential & Sensitive Areas, Height & Space Restrictions, Shallow Wells and Offshore Platforms, Urban Drill Sites, Directional Wells, High Density Fields, Agricultural Installations, Visually Sensitive Areas

Keeping wells pumping since 1987

HRP International was established in 1987 Los Angeles California to answer the oil industry's call to provide pumping units that are ultra reliable, low profile, low maintenance and used in highly sensitive area.

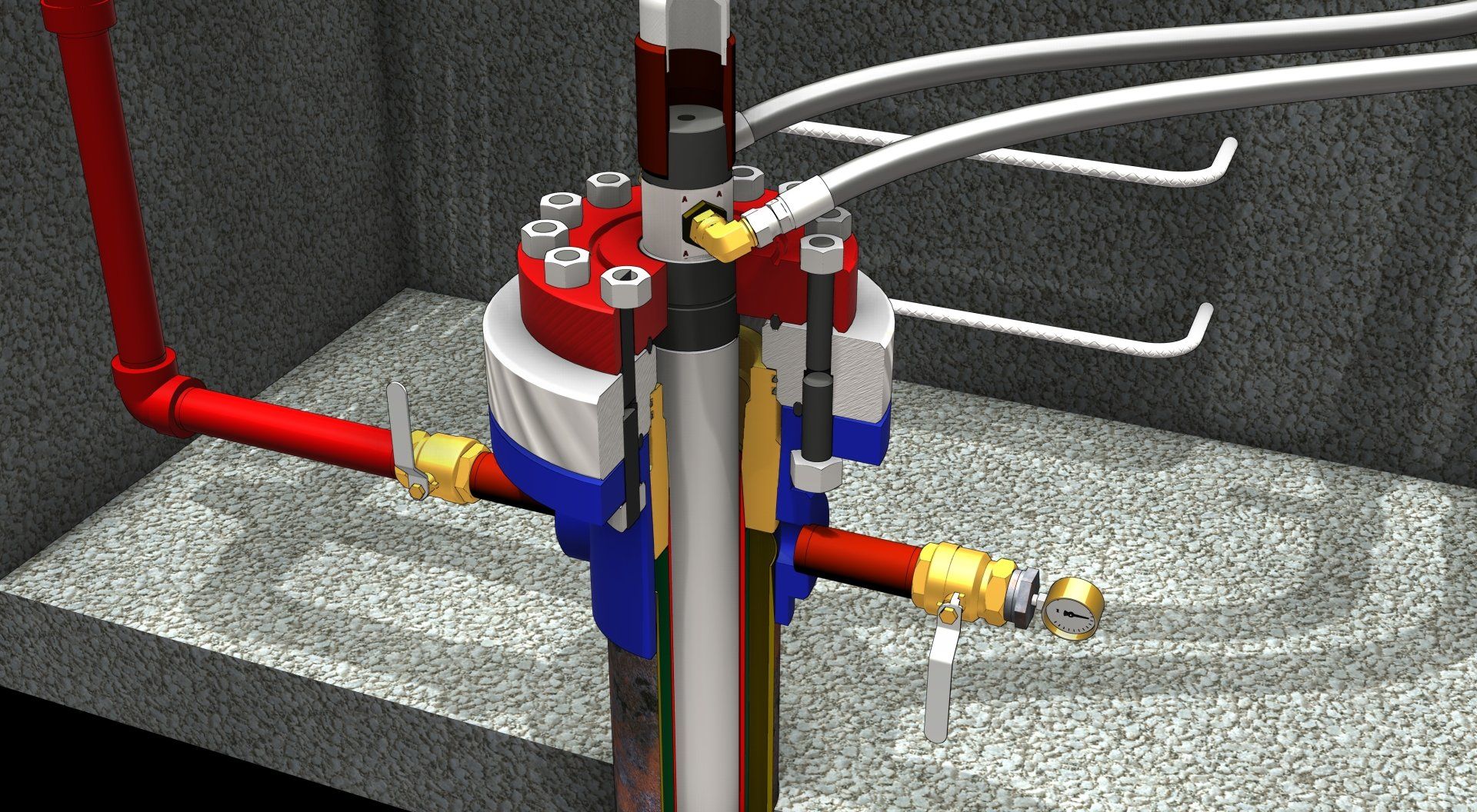

We answered that call and invented the world's 1st and only Below Ground Hydraulic Cylinder. Years of innovation, research & development had enabled us to be the forefront of hydaulic rod pumping technolgy.

Today our technology for both the below Ground and Above Ground Cylinder are used around the world at some of the most challenging wells.

When you pursue excellence, success will follow.

Ultra Long Stroke

- 60" to 336" stroke length

- Reduced repetitive rod stress

- Less rod & tubing Wear

- Linear rod velocity optimizes production & equipment life

- Greater down hole pump efficiency

- Reduces rod loads, buckling & compression.

Low Profile

- Much smaller footprint compared to conventional pump jacks

- Subsurface cylinders allow for minimal wellhead footprint

- Great for high density drill sites

- Semi-Portable for easy well to well relocation.

Environment & Safety

- No stuffing box – Completely eliminate stuffing box leaks

- No electrical components on wellhead - hazardous zone safe

- No working at heights

- Eliminating gas emissions from leaking stuffing box

Best in Class Reliability

- 33 years of research & development

- Field proven reliability results

- Advance and proprietary hydrau-mechanics

- No leak path on wellhead

- HPU designed to greatly reduce leaks through spill protecion.

- Units operational since 1987

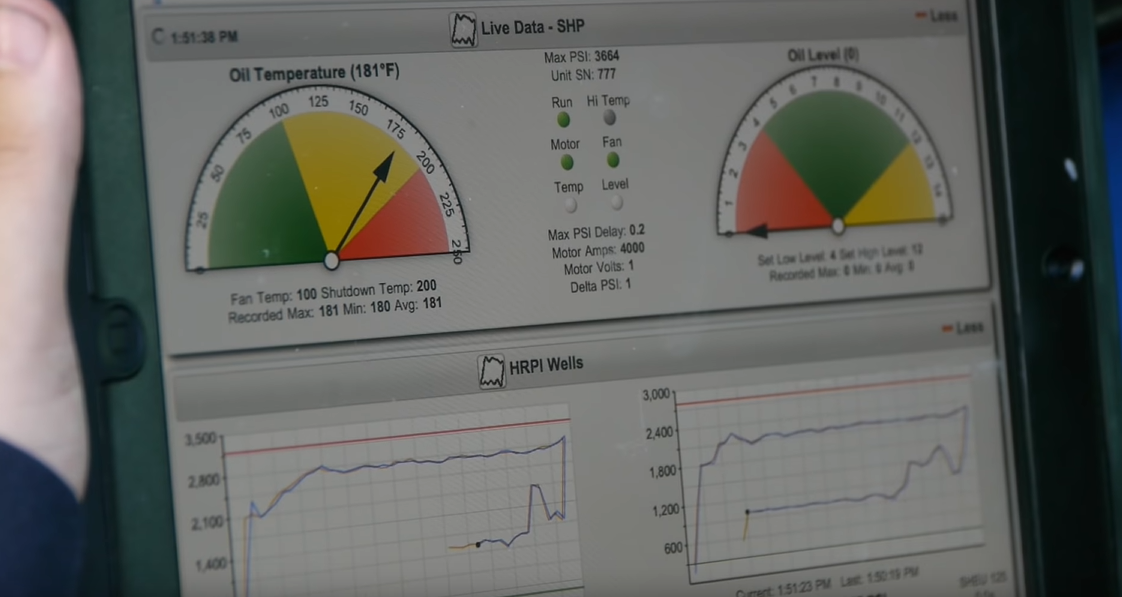

Advance Controls

- Pumping speed (SPM) adjustment

- Live and historical dynocards

- Smart pump-off controller

- Programmable up and downstroke velocity

- Complete well history and data trend

- Local and wireless controls and monitoring

Product Offering

Our packages are fully plug and play and made for simplicity

-

HYDRAULIC PUMPING UNIT

Learn More -

ABOVE GROUND CYLINDER

Learn More -

BELOW GROUND CYLINDER

Learn More -

PUMP CONTROLLER

Learn More

“Our company founder taught us long ago that quality must be placed above all else, because our (and the customer's) livelihood relies solely upon our product's reliability & uptime.”

Chris Hodges, Hydraulic Rod Pumps, Int'l CEO

Contact Us

We’d love to hear from you. Call us at +1 (949) 452-1111 or send us a message using the form below and we’ll get back to you as soon as we can.

Thank you for contacting us.

We will get back to you as soon as possible

We will get back to you as soon as possible

Oops, there was an error sending your message.

Please try again later

Please try again later