HRP

Advance Pump Controller

The first and only below ground hydraulic cylinder in the industry. Designed for the most sensitive of applications.

Features & Benefits

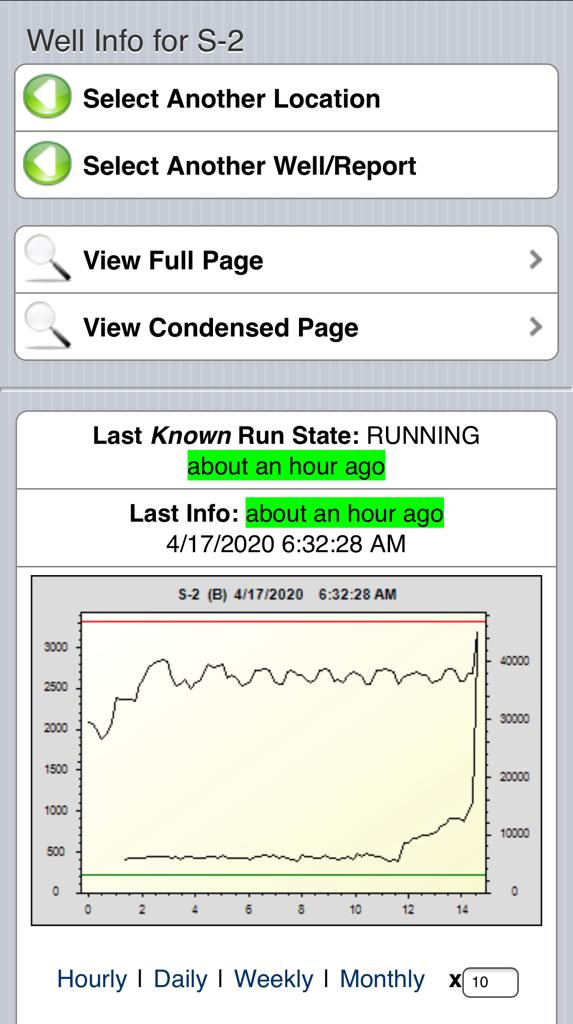

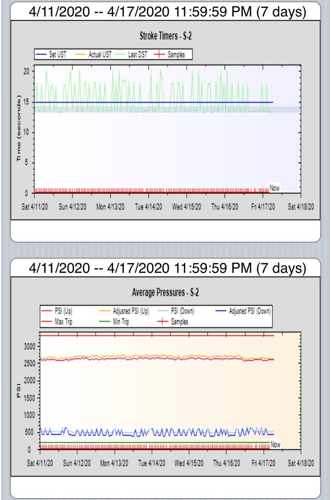

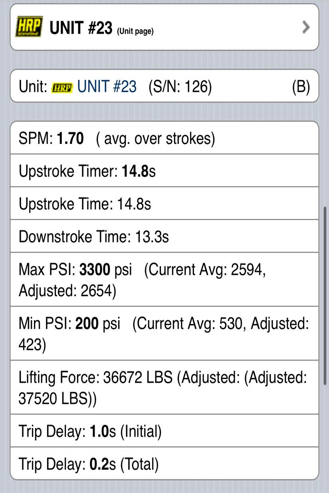

HRPI equipment provides advanced computer control, monitoring, and diagnostics. The most notable control feature of the system is the ability to remotely adjust the well's Strokes Per Minute (SPM). This allows for a more optimized pump rate given changing conditions.

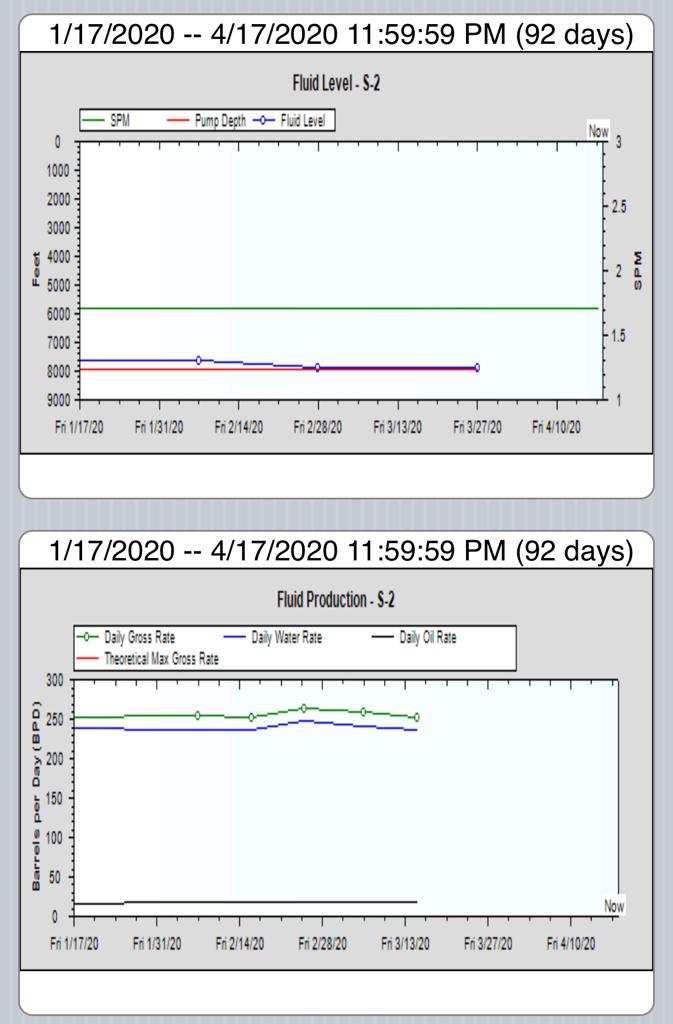

Live dyno graphs are streamed as they are collected, stored both locally and on a central webbased analysis server.

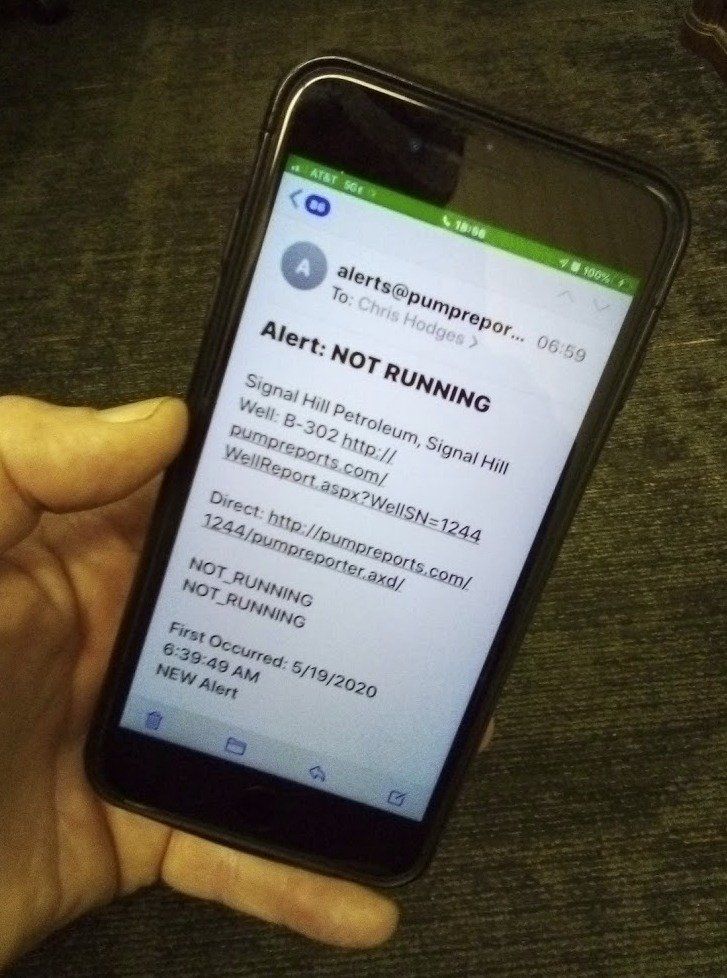

Web based monitoring, alerting, and analysis is provided through http://pumpreports.com. Access to historical well information, current operating parameters, dynos, and trend graphs are available securely from any standard web browser.